16.1: Distribution Channels

16.1.1: Marketing Intermediaries

Intermediaries are a powerful resource that enable organizations to outsource specific business functions in order to focus more on their core competency.

Learning Objective

Identify the value of various intermediaries, and understand which situations call for collaboration with them

Key Points

- Intermediaries take on key responsibilities of the value chain for organizations, such as shipping, retail, e-commerce, storage, web development, and marketing.

- Through utilizing intermediaries well, organizations can capture significant time and capital savings that can instead be invested into the core competency of the company.

- Distribution is a strong example of intermediaries, where an organization collaborates with Fedex or UPS in order to move their goods to their customers. Creating a shipping competency internally would be much more expensive.

- Retail and e-commerce are also common examples of intermediaries. Instead of purchasing expensive property to build storefronts, a fashion designer could instead sell their goods wholesale to established retail outlets.

- Understanding when to outsource something to an intermediary, and when to build the competency in house, is a key area of strategic decision-making.

Key Terms

- intermediaries

-

Organizations that act as a provider of a specific function or service for other organizations.

- e-commerce

-

A marketplace for the exchange of goods that exist solely online.

Why Use Intermediaries

Product distribution is the way an organization moves a product into the hands of their consumers. Most organizations focus on the design and production of the product or service they sell, and not on the distribution channels that connect them to the users themselves. Instead, they outsource many of these aspects to intermediaries.

Intermediaries are specialists for a specific function along the value chain. This could include distribution, marketing, sales, retail, e-commerce, web development, branding, packaging, storing, and a variety of other functions. Collaborating with one or more partners can enable an organization to focus on what it is that they do best (core competency) and, in turn, outsource other aspects of the value chain to organizations who are best at that particular function.

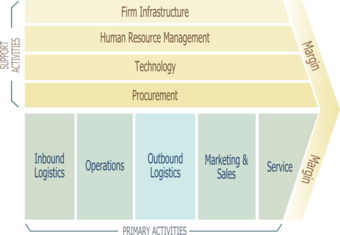

Porter Value Chain

Understanding the value chain is central to the concept of intermediaries. The value chain shows all the steps a business must take to get a product developed from the raw materials and into the hands of the consumer. Organizations benefit significantly from understanding the opportunity cost of intermediaries.

Common Intermediaries

Distribution

Some of the most common intermediaries are related to product distribution. Moving a good from the producer to the buyer is a logistically complex and resource-heavy process. Ensuring that shipping resources are available (e.g., trucks, ships, planes, and trains primarily) and that items move from supplier to warehouse to user is often handled by an intermediary such as Fedex or UPS. These organizations can utilize economies of scale and a vast network of resources to offer highly specialized delivery services at a relatively low cost and, more importantly, low risk.

Retail

Buying real estate to store and sell physical goods can be extremely cost prohibitive. Investing in retail outlets all across the world requires a huge amount of fixed investments, and likely will incur a high amount of debt. This debt is a business risk most smaller producers do not want to incur. As a result, they sell their items wholesale to various retail outlets. This allows both parties to mitigate risk, as the retailer can sell a variety of goods without having to produce them all, and the producer can acquire sales channels across the globe without investing significantly in real estate.

Consider a store like Macy’s, where the shelves are stocked with brand name goods. Macy’s in downtown Manhattan is an expensive piece of land, but the suppliers themselves are not liable for the purchase and maintenance of that property. Instead, Macy’s diversifies its portfolio of goods while producers provide them at lower wholesale prices to share risk.

Ad Agencies

Another popular intermediary is the ad agency. Ad agencies specialize in building communities and brands, utilizing a wide variety of paid and organic channels. This can include social networks such as Facebook, Linkedin, Twitter and Instagram, as well as paid ad production on popular TV channels or affiliate advertising. Ad agencies utilize the entire marketing mix (and more, nowadays) to craft customized brand building initiatives centered on the unique target market and product of their strategic partners.

E-commerce and Web Development

Maintaining an online storefront nowadays is relatively straight-forward, so more and more companies do this internally now. However, managing a large e-commerce team with strong web development skills (such as copy, graphic design, UX, and other e-commerce roles) can become a pricey endeavor. As a result, some organizations prefer outsourcing this as well.

Amazon is a great example of an e-commerce website designed to enable smaller businesses. Amazon actually handles quite a bit of intermediary responsibilities (i.e. shipping, storing, and e-commerce for starters). The value Amazon adds is not only limited to the skills of building strong websites, however. Amazon has a huge and loyal following of consumers, which makes them an attractive potential strategic alliance for many smaller firms.

Conclusion

What’s most important to understand about intermediaries is that they are a trade-off, where an organization recognizes the value of outsourcing a function relative to the opportunity cost of building that competency internally. When considering working with a third party, consider the core competency of that partner compared to the core competency of your own organization and determine if synergy exists (as opposed to redundancy).

16.1.2: The Value of Intermediaries

Utilizing intermediaries reduces organizational complexity and allows firms to focus on developing a core competency through specialization.

Learning Objective

Outline the various benefits of utilizing intermediaries, and understand how to capture value from the process

Key Points

- The primary advantage of intermediaries is the ability to focus specifically on what your organization does best. This is called specialization.

- Building internal capabilities in a variety of complicated fields, such as legal, HR, accounting, BI and countless other disciplines, is often a significant investment of time and resources as well as a source of risk.

- Organizations with many different departments focused on a wide variety of disciplines is likely to lose some agility due to complexity.

- Intermediaries that focus on doing one thing best for a wide variety of strategic partners will likely realize economies of scale. This means that by doing something in high volume, the marginal cost of additional units is significantly lower.

- Through utilizing intermediaries along the value chain, firms can maintain simple, specialized core competencies while mitigating risk and capturing economies of scale via similarly specialized partners.

Key Terms

- intermediaries

-

Organizations or individuals that fulfill tasks on behalf of other organizations.

- specialization

-

The ability to focus on one specific task, and create an advantage through excelling at this task.

Why Use Intermediaries?

Organizations use intermediaries in order to allow themselves to focus on their core competency and/or competitive advantages. This creates the economic advantage of specialization, and enables multiple strategic partners to collaborate on the design, production, and distribution of countless goods and services.

An Example

For example, assume you own a company that produces top quality audio equipment (speakers, surround sound, headphones, etc.). Your sound engineers are some of the best in the business, but you have limited resources. When it comes to retailing your items, you don’t have the capital to purchase property and open stores. So you use a marketing intermediary, and work with companies that sell music equipment. You also don’t have the capital to open a mass manufacturing facility, so you outsource your production to specialists in audio manufacturing. Instead of building a complex tax and finance team, you hire an accounting firm.

Next thing you know, your sound engineers, innovators, researchers and core managers are the only internal employees of your organization. The rest are value-adding intermediaries who limit your risk and allow you to focus on what you do best.

The Advantages of Intermediaries

Building relationships with various strategic partners along your value chain can be a significant source of competitive advantage and agility in the modern, hugely fast-paced world of business. A few key advantages in a general sense include:

- Specialization and Focus – As discussed above, often one of the primary advantages of utilizing intermediaries is the ability to increase focus on a business’ core products and core competency. Additionally, whomever the intermediary is shares this advantage. As a result, organizations with many intermediaries can benefit from the specializations of their partners.

- Economies of Scale – On a per output basis, it is often the case that higher volume leads to lower costs per unit. If an organization were to build its own shipping and logistics department, the cost per shipment would almost certainly be higher than that of Fedex or UPS. These organizations have developed scale while perfecting their process, an advantage a small organization will find nearly impossible to duplicate.

- Risk Mitigation – Trying to do everything means taking all the corresponding risks that everything has to offer. For example, an organization that takes on its own accounting and financial management will incur the risk of making tax mistakes and the fines that come along with it.

- Agility – A larger organization with more moving parts, including retail, manufacturing, taxes and accounting, finance, marketing, operational management, HR, legal, database management, IT and all the other various potential requirements of modern business must face the challenge of coordinating all of these work groups towards a shared objective. This higher degree of organizational inertia is likely to significantly reduce a business’ ability to progress and adapt to change.

While there are other advantages of intermediaries depending on the situation, this chart captures the broader reasoning behind the strategy of collaborating externally to fulfill certain operational requirements.

The Value Chain

The Value Chain is a great way to visualize where intermediaries could potentially exist within a given organization. Organizations tend to complete each of these tasks in some way, and outsourcing a variety of them is a useful starting point for specializing through intermediaries and strategic alliances.

16.1.3: The Cost of Intermediaries

While organizations gain advantage by collaborating with intermediaries, there are costs involved to consider.

Learning Objective

Understand the various costs which accompany product distribution when working with intermediaries

Key Points

- Distribution of goods from a provider to a consumer often includes interaction with a number of different intermediaries.

- Financial intermediaries, such as banks, enable the capital exchange behind a given transaction. This usually incurs a cost to either (or both) the consumer and the business.

- Physical storage and shipping is a resource and time intensive process, which incurs additional costs in the transaction.

- Storefronts, both digital and physical, often add a small amount to the sale price in order to cover the cost of a business’s location, staff, and other overhead.

- When considering distribution, it is important to recognize the value added by intermediaries, and the subsequent cost involved in collaboration.

Key Term

- intermediaries

-

A third-party that acts as a go-between in a given transaction

Distribution of goods is often enabled through collaboration with partners and intermediaries. While this is generally a mutually advantageous situation, where margins are captured by all parties, it is still worth briefly exploring how a given business is impacted by the cost of collaboration.

Common Costs of Intermediaries

While the intermediaries required will differ based on the product or service being discussed, there are a few common costs which most business can anticipate incurring when it comes to product distribution:

Financial Intermediaries – Transactions are the core function of exchange in the modern economy, where a good or service is transferred for a capital payment. This capital exchange is largely governed by banks. Costs are usually incurred to one or both parties during these exchanges, often as a percentage of the overall capital exchanged.

Shipping Intermediaries – Getting an item from the business to the user often requires shipping and warehousing. This service can be expensive due to the costs of transportation, and the necessity for holding inventory at various supply centers. As a result, either or both parties will likely incur costs for this service.

Marketing Intermediaries – Storefronts, be they online or physical locations, are convenient and comfortable contact points for products and consumers. As a result of the physical location, staffing, and inventory costs incurred by the storefronts themselves, either or both parties in the exchange are likely to incur costs.

There are various other intermediaries (legal, customer support, etc.), but this provides a general framework for common areas of collaboration when bringing a product or service from the business to the consumer.

Intermediaries in Context

Let’s consider an example. A consumer goes online to purchase a new tablet. For the sake of discussion, let’s say it is a Microsoft tablet being purchased from Amazon. From the perspective of the firm which created the product (Microsoft), there are quite a few intermediaries between the consumer and themselves as a producer:

- First is the storefront the consumer purchases it from, in this case Amazon. Naturally, Amazon will have marked up the price of the product in order to maintain profitability (with some exceptions).

- Next comes the payment provider. Amazon will link you with a bank or other financial provider (i.e. PayPal, bitcoin, etc.) to process the payment. This will also incur some cost.

- Following this, we still need to get the product from Amazon to the consumer’s doorstep. Shipping and handling fees will be applied.

As is demonstrated in this example, Microsoft’s product will incur various costs, some of which will be shouldered by Microsoft, and some which will be handled by the end consumer. During this process an ecosystem emerges where mutual value is gained by all parties throughout the transaction. While these costs are relevant strategically, so too are the benefits organizations derive from the process.

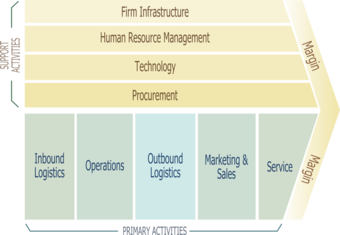

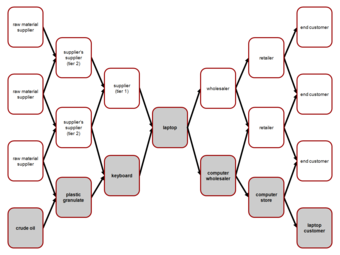

Intermediaries

This image shows a simple supply chain, including the various distribution intermediaries a company may work through in order to provide a customer with a product.

16.1.4: Channels for Consumer Goods

Marketing channels are sets of interdependent organizations involved in making a product or service available for use or consumption.

Learning Objective

Define a marketing channel in the modern complex distribution network

Key Points

- First, the channel consists of institutions, some under the control of the producer and some outside the producer’s control. Yet all must be recognized, selected, and integrated into an efficient channel arrangement.

- Second, the channel management process is continuous and requires constant monitoring and reappraisal. The channel operates 24 hours a day and exists in an environment where change is the norm.

- Finally, channels should have certain distribution objectives guiding their activities. The structure and management of the marketing channel is thus in part a function of a firm’s distribution objective. It is also a part of the marketing objectives, especially the need to make profit.

Key Term

- channels of distribution

-

Distribution of products takes place by means of channels. Channels are sets of interdependent organisations (called intermediaries) involved in making the product available for consumption.

With the growth of specialization, particularly industrial specialization, and with improvements in methods of transportation and communication, channels of distribution have become very complex. Thus, corn grown in Illinois may be processed into corn chips in West Texas, which are then distributed throughout the United States. Or, turkeys grown in Virginia are sent to New York so that they can be shipped to supermarkets in Virginia. Channels don’t always make sense. The channel mechanism also operates for service products. In the case of medical care, the channel mechanism may consist of a local physician, specialists, hospitals, ambulances, laboratories, insurance companies, physical therapists, home care professionals, and so forth. All of these individuals are interdependent, and could not operate successfully without the cooperation and capabilities of all the others.

Based on this relationship, a marketing channel can be defined as “sets of interdependent organizations involved in the process of making a product or service available for use or consumption, as well as providing a payment mechanism for the provider. ” This definition implies several important characteristics of the channel.

First, the channel consists of institutions, some under the control of the producer and some outside the producer’s control. Yet all must be recognized, selected, and integrated into an efficient channel arrangement.

Second, the channel management process is continuous and requires constant monitoring and reappraisal. The channel operates 24 hours a day and exists in an environment where change is the norm.

Finally, channels should have certain distribution objectives guiding their activities. The structure and management of the marketing channel is thus in part a function of a firm’s distribution objective. It is also a part of the marketing objectives, especially the need to make an acceptable profit. Channels usually represent the largest costs in marketing a product.

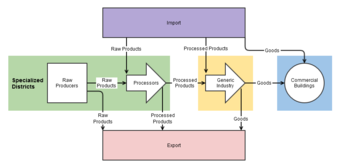

Selecting the channel

Selecting the right modes of transport is also very important in saving costs

16.1.5: Channels for Industrial Goods

Creating efficient and cost-effect channels for industrial goods can create value for business-to-business exchanges.

Learning Objective

Differentiate between consumer and industrial channels, and understand how to increase efficiency in B2B exchange

Key Points

- Industrial distribution channels mostly refer to business-to-business (B2B) transactions of relatively high volume. As a result, the channel strategy tends to be a bit different than that of consumer goods.

- One of the most important decisions in a B2B channel is choosing the way goods are transported. This could be via road, rail, ship, or plane.

- Channels of exchange are also rife with intermediaries, such as logistics companies, who expedite the process of exchange.

- In industrial distribution, contracts tend to be carefully negotiated, high volume, and continuous.

Key Term

- intermediaries

-

A person or organization in an intermediate position in a supply chain of goods or services

Industrial Goods

To understand industrial distribution channels, it’s important to realize that industrial goods generally refer to business-to-business (B2B) transactions of relatively high volume. When business enter exchange agreements, the contracts tend to involve large shipments that are repeated consistently over an agreed period of time.

With this in mind, the distribution strategy of industrial goods tends to be different than the distribution channels commonly utilized in business-to-consumer (B2C) transactions (such as retail outlets).

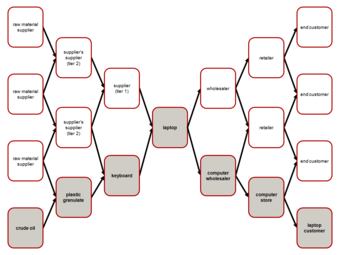

Industrial Channels

This image depicts the sourcing of raw materials, and the exchange of industrial goods between various businesses in the construction industry. As you can see, there are many channels in any given industry, and the exchange between organizations in big business.

Industrial Channel Considerations

Generally speaking, the distribution of industrial goods is planned carefully, negotiated in advance, and focused on maximizing cost savings through effective logistics. While there are many factors that may influence channel decisions, management generally needs to determine which modes of transportation to use, how to warehouse goods, environmental requirements (temperature, for example), intermediaries, and scheduling.

Mode of Transport

Getting goods from A to B requires a mode of transportation, and each will come with various tradeoffs. For the most part, these tradeoffs revolve around speed and capacity (how fast something can be moved, and how much of it). For industrial goods, the most common options are road, rail, ship, and plane.

- Ship – Cheap, slow, and limited to places with ports, ship transportation is excellent for high volume orders with no time constraints.

- Road – The trucking industry in the United States alone is a massive undertaking, with movement of goods happening around the clock. This is great for specificity in terms of location, and tends to be fairly fast.

- Rail – Rail is an extremely cheap option, due to the low labor and resources involved. Rail, however, has the key weakness of only going where there are tracks.

- Plane – The fastest, most accurate and most expensive form of transportation, air transportation is good for transporting a small volume of goods rapidly to a specific location.

Storage

Getting goods from A to B is only part of distribution. There will also be time between using a purchased asset and receiving it. This will be in the form of storage. Storage considerations are fairly simple: where to store goods, how much it will cost, how much space will be required, and what environment they should be stored in.

Intermediaries

Sometimes organizations use intermediaries, such as UPS or Fedex, to improve upon the logistics involved. These organizations specialize in minimizing the cost of transportation (through economy of scale), and take on the responsibility of moving, storing, and maintaining the goods as they are transported between the two bartering parties. Of course, intermediaries must turn a profit too, so the cost savings must offset the cost of the intermediary.

Conclusion

All and all, the channels involved in selling industrial goods between businesses are mostly about moving a high volume of goods from the producer to the buyer, often using a third party to handle the logistics.

16.2: Wholesalers

16.2.1: Merchant Wholesalers

Wholesale merchants, agents, and brokers help move goods between producers and retailers.

Learning Objective

Distinguish between the roles of wholesale merchants, agents, and brokers

Key Points

- Wholesale merchants, agents, and brokers are essential elements of the wholesale business. They help move goods between producers and retailers and the advent of modern technologies help them do this more efficiently.

- A wholesale merchant operates in the chain between producer and retail merchant. Some wholesale merchants only organize the movement of goods rather than move the goods themselves.

- In the wholesale business, wholesale agents and brokers do not take title to the merchandise being marketed, they only bring buyers and sellers together and negotiate the terms of the transaction.

Key Terms

- merchant wholesaler

-

an entity that purchases products, takes title of them, and then sells them (generally to retailers, other wholesalers, and industrial consumers)

- wholesale

-

The sale of products, often in large quantities, to retailers or other merchants.

- brokers

-

A mediator between a buyer and seller.

Wholesale merchants, agents, and brokers are essential elements of the wholesale business. They help move goods between producers and retailers and the advent of modern technologies help them do this more efficiently.

A wholesale merchant operates in the chain between the producer and the retail merchant. Some wholesale merchants only organize the movement of goods rather than move the goods themselves. Limited service merchant wholesalers take title to the merchandise and assume the risk involved in an independent operation. They buy and resell products and offer a limited range of services. Since wholesale activities can be assumed by the suppliers themselves, those merchant wholesalers who have remained viable have done so by providing improved service to suppliers and buyers. To do this at low cost, modern technologies must be increasingly integrated into the wholesale operation.

In the wholesale business, wholesale agents and brokers do not take title to the merchandise being marketed, they only bring buyers and sellers together and negotiate the terms of the transaction. Agent merchants represent their the buyer or seller, usually on a permanent basis; brokers bring parties together on a temporary basis. Brokers have the tools and resources to reach the largest possible base of buyers. They then screen these potential buyers for revenue that would support the potential acquisition. An individual producer, on the other hand, especially one new in the market, probably will not have the same access to customers as a broker. Another benefit of using a broker is cost—they might be cheaper in smaller markets, with smaller accounts, or with a limited line of products.

A Merchant

Merchants from Holland and the Middle East trading.

16.3: Retailers

16.3.1: Store Retailers

Store retailers vary in size, in the kinds of services, the assortment of merchandise they carry, and many other respects.

Learning Objective

Compare the different types of store retail facilities

Key Points

- Department stores are characterized by their very wide product mixes. That is, they carry many different types of merchandise that may include hardware, clothing, and appliances.

- Chain Stores: The 1920s saw the evolution of the chain store movement. Because chains were so large, they were able to buy a wide variety of merchandise in large quantity discounts.

- Supermarkets were among the first to experiment with such innovations as mass merchandising and low-cost distribution methods.

- Warehouse retailing is a relatively new type of retail institution that experienced considerable growth in the 1970s.

Key Term

- franchising

-

Franchising is the practice of using another firm’s successful business model.

Store Retailers

Store retailers vary in size, in the kinds of services that are provided, in the assortment of merchandise they carry, and in many other respects. Most stores are small and have daily sales of only a few hundred dollars. Few are extremely large, having sales of $500,000 or more on a single day. In fact, on special sale days, some stores have exceeded $1 million in sales.

Department Stores: Department stores are characterized by their very wide product mixes. That is, they carry many different types of merchandise that may include hardware, clothing, and appliances. Each type of merchandise is typically displayed in a different section or department within the store. The depth of the product mix depends on the store.

Chain Stores: The 1920s saw the evolution of the chain store movement. Because chains were so large, they were able to buy a wide variety of merchandise in large quantity discounts. The discounts substantially lowered their cost compared to costs of single-unit retailers. As a result, they could set retail prices that were lower than those of their small competitors and, thereby, increase their share of the market. Furthermore, chains were able to attract many customers because of their convenient locations, made possible by their financial resources and expertise in selecting locations.

Supermarkets: Supermarkets evolved in the 1920s and 1930s. For example, Piggly Wiggly Food Stores, founded by Clarence Saunders around 1920, introduced self-service and customer checkout counters. Supermarkets are large, self-service stores with central check-out facilities, they carry an extensive line of food items and often non-food products. Supermarkets were among the first to experiment with such innovations as mass merchandising and low-cost distribution methods. Their entire approach to the distribution of food and household cleaning and maintenance products was to make available to the public large assortments of a variety of such goods at each store at a minimal price.

Discount Houses: Cut-rate retailers have existed for a long time. However, since the end of World War II, the growth of discount houses as a legitimate and extremely competitive retailer has assured this type of outlet a permanent place among retail institutions. It essentially followed the growth of the suburbs. Discount houses are characterized by an emphasis on price as their main sales appeal. Merchandise assortments are generally broad, including both hard and soft goods, but assortments are typically limited to the most popular items, colors, and sizes. Such stores are usually large, self-service operations with long hours, free parking, and relatively simple fixtures.

Warehouse Retailing: Warehouse retailing is a relatively new type of retail institution that experienced considerable growth in the 1970s. Catalog showrooms are the largest type of warehouse retailer, at least in terms of the number of stores operated. Their growth rate has slowed in comparison to previous decades, but they still have a huge presence in terms of their sales.

Franchises: Over the years, particularly since the 1930s, large chain store retailers have posed a serious competitive threat to small store owners. One of the responses to this threat has been the rapid growth of franchising. Franchising is not a new development. The major oil companies such as Mobil have long enfranchised its dealers, who only sell the products of the franchiser (the oil companies). Automobile manufacturers also enfranchise their dealers, who sell a stipulated make of car (e.g., Chevrolet) end operate their business to some extent as the manufacturer wishes.

Planned Shopping Centers: After World War II, the United States underwent many changes. Among those most influential on retailing were the growth of the population and of the economy. New highway construction enabled people to leave the congested central cities and move to newly developed suburban residential communities. This movement to the suburbs established the need for new centers of retailing to serve the exploding populations. By 1960 there were 4,500 such centers with both chains and non-chains vying for location. Such regional shopping centers are successful because they provide customers with a wide assortment of products. If you want to buy a suit or a dress, a regional shopping center provides many alternatives in one location.

Macy’s Department Store

The Macy’s flagship department store with the famous brownstone at 34th and Broadway.

16.3.2: Nonstore Retailers

Non-store retailing is the selling of goods and services outside the confines of a retail facility.

Learning Objective

Discuss non-store retailing as a sales channel

Key Points

- E-commerce is growing by leaps and bounds, as consumers become more comfortable with the concept and their options increase.

- In total, non-store retailing accounts for a relatively small percentage of total retail sales, but it is growing and very important with certain types of merchandise, such as life insurance, cigarettes, magazines, books, CDs, and clothing.

- The non-store distribution channel can be divided into direct selling (off-premises sales), and distance selling, the latter include all forms of electronic commerce.

Key Term

- Direct selling

-

Direct selling is the marketing and selling of products directly to consumers away from a fixed retail location.

Non-store retailing is the selling of goods and services outside the confines of a retail facility. It is a generic term describing retailing taking place outside of shops and stores (i.e., off the premises of fixed retail locations and of markets stands). The non-store distribution channel can be divided into direct selling (off-premises sales) and distance selling, the latter including all forms of electronic commerce. Distance selling includes mail order, catalogue sales, telephone solicitations, and automated vending. Electronic commerce includes online shopping, Internet trading platforms, travel portals, global distribution systems, and teleshopping. Direct selling includes party sales and all forms of selling in consumers’ homes and offices, including even garage sales.

E-commerce is growing by leaps and bounds, as consumers become more comfortable with the concept and their options increase. Flash deal sites have been the trend of the moment, where consumers generally have a membership with a specific site and are given access to a limited-time price on a good. E-commerce sites now cover almost every nook and cranny of the retail space. You can go to the wildly successful Alibaba.com to buy machinery from Asia. You can go to CustomMade.com to purchase a good made specifically for you by one of those same machines. With all the e-commerce growth comes interesting trends relating to consumers becoming more comfortable with making purchase on their mobile phones and tablets. Mobile phones also aid purchases everywhere now more than ever, and play a crucial role in any retailer’s marketing strategy.

In total, non-store retailing accounts for a relatively small percentage of total retail sales, but it is growing and very important with certain types of merchandise, such as life insurance, cigarettes, magazines, books, CDs, and clothing. One type of non-store retailing used by such companies as Avon, Electrolux, and many insurance agencies is in-home selling. Such sales calls may be made to preselected prospects or in some cases on a cold call basis. A variation of door-to-door selling is the demonstration party. Here one customer acts as a host and invites friends. Tupperware has been very successful with this approach. Vending machines are another type of non-store retailing. Mail order is a form of non-store retailing that relies on product description to sell merchandise. The communication with the customer can be by flyer or catalog. Magazines, CDs, clothing, and assorted household items are often sold in this fashion. Mail order offers convenience but limited service, and it is an efficient way to cover a very large geographical area when shoppers are not concentrated in one location.

Tupperware Party

Tupperware party in the 1960’s.

16.3.3: Internet Retailers

Online retailing is a form of electronic commerce where consumers directly buy goods or services from a seller using the Internet.

Learning Objective

Outline the process of online shopping

Key Points

- An online shop, e-store, or virtual store evokes the physical analogy of buying products or services at a shopping center. The process is called business-to-consumer (B2C) online shopping. When a business buys from another business, it is called business-to-business (B2B) online shopping.

- Consumers find a product of interest by visiting the website of the retailer directly or by searching among alternative vendors using a shopping search engine. A “checkout” process follows in which payment and delivery information is collected, if necessary.

- Once a payment has been accepted the goods or services can be delivered in the following ways: downloading, shipping, in-store pick up, “at the door” pick up, and printing out or emailing.

Key Term

- electronic commerce

-

Electronic commerce, commonly known as e-commerce, is the buying and selling of products or services over electronic systems such as the Internet and other computer networks.

Internet Retailers

Online retailing is a form of electronic commerce whereby consumers directly buy goods or services from a seller over the Internet without an intermediary. An online shop, eshop, e-store, Internet shop, webshop, webstore, online store, or virtual store evokes the physical analogy of buying products or services at a bricks-and-mortar retailer or shopping center. The process is called business-to-consumer (B2C) online shopping. When a business buys from another business it is called business-to-business (B2B) online shopping. The largest online retailing corporations are eBay and Amazon.com, both of which are US-based .

Amazon.com Headquarters

This is the headquarters of Amazon.com, the largest online retailer in the world.

The Process of Shopping Online

Consumers find a product of interest by visiting the website of the retailer directly or by searching among alternative vendors using a shopping search engine. Once a particular product has been found on the web site of the seller, most online retailers use shopping cart software to allow the consumer to accumulate multiple items and to adjust quantities, much similar to the process of filling a physical shopping cart or basket in a conventional store. A “checkout” process follows (continuing the physical-store analogy) in which payment and delivery information is collected, if necessary.

Some stores allow consumers to sign up for a permanent online account so that some or all of this information only needs to be entered once. The consumer often receives an e-mail confirmation once the transaction is complete. Less sophisticated stores may rely on consumers to phone or e-mail their orders (though credit card numbers are not accepted by e-mail, for security reasons). Online shoppers commonly use a credit card to make payments, but some systems enable users to create accounts and pay by alternative means, such as: billing to mobile phones and landlines, cash on delivery (or C.O.D., which is offered by very few online stores), checks, and wire transfers.

The Methods of Delivery

Once a payment has been accepted, the goods or services can be delivered in the following ways:

Downloading: This method is often used for digital media products such as software, music, movies, or images.

Drop shipping: The order is passed to the manufacturer or third-party distributor, who ships the item directly to the consumer, bypassing the retailer’s physical location to save time, money, and space.

In-store pickup: The customer orders online, finds the closest local store using locator software and picks the product up there. This method is often used in the bricks and clicks business model.

Printing out, provision of a code for, or emailing of such items as admission tickets and scrip (e.g., gift certificates and coupons): The tickets, codes, or coupons may be redeemed at the appropriate physical or online premises and their content reviewed to verify their eligility (e.g., assurances that the right of admission or use is redeemed at the correct time and place, for the correct dollar amount, and for the correct number of uses).

Shipping: The product is shipped to the customer’s address or that of a customer-designated third party.

Will call, in care of box office (ICOBO), or “at the door” pickup: The patron picks up pre-purchased tickets for an event, such as a play, sporting event, or concert, either just before the event or in advance. With the onset of the Internet and e-commerce sites, which allow customers to buy tickets online, the popularity of this service has increased.

16.3.4: Telemarketing

Telemarketing is a method of direct marketing where a salesperson solicits prospective customers directly, usually over the phone.

Learning Objective

Break down the elements of telemarketing

Key Points

- Telemarketing can also be done through a subsequent face-to-face or Web conferencing appointment scheduled during the call, and can include recorded sales pitches programmed to be played over the phone via automatic dialing.

- Telemarketing has come under fire in recent years, being viewed as an annoyance and a disturbance by many.

- Prospective customers are identified by various means, including past purchase history, previous requests for information, credit limit, competition entry forms, application forms, or purchases from another company’s consumer database or obtained from a telephone directory or another public list.

Key Term

- robocalling

-

a form of voice broadcasting which is most frequently associated with political messages.

Telemarketing

Telemarketing is a method of direct marketing in which a salesperson solicits prospective customers to buy products or services, either over the phone or through a subsequent face-to-face or Web conferencing appointment scheduled during the call . Telemarketing can also include recorded sales pitches programmed to be played over the phone via automatic dialing. Telemarketing has come under fire in recent years, being viewed as an annoyance and a disturbance by many. While many methods of marketing will suffer this criticism to some degree by those who prefer not to be disturbed, telemarketing seems to be criticized particularly because of its direct, intrusive nature. The two major categories of telemarketing are business-to-business and business-to-consumer.

Telemarketing

Author and activist Bob Wood places one of his numerous phone calls to residents in Muskegon County, Michigan.

Some important terms used in telemarketing are:

- Lead Generation – the gathering of information and contacts.

- Sales – using persuasion to sell a product or service.

- Outbound – proactive marketing in which prospective and preexisting customers are contacted directly.

- Inbound – reception of incoming orders and requests for information.

Demand is generally created by advertising, publicity, or the efforts of outside salespeople. Telemarketing may be done from a company office, from a call center, or from home. It may involve either a live operator or a recorded message, in which case it is known as “automated telemarketing” using voice broadcasting. “Robocalling” is a form of voice broadcasting that is most frequently associated with political messages. An effective telemarketing process often involves two or more calls. The first call (or series of calls) determines the customer’s needs. The final call (or series of calls) motivates the customer to make a purchase.

Prospective customers are identified by various means, including past purchase history, previous requests for information, credit limit, competition entry forms, and application forms. Names may also be purchased from another company’s consumer database or obtained from a telephone directory or another public list. The qualification process is intended to determine which customers are most likely to purchase the product or service. Charitable organizations, alumni associations, and political parties often use telemarketing to solicit donations. Marketing research companies use telemarketing techniques to survey the prospective or past customers of a client’s business in order to assess market acceptance of or satisfaction with a particular product, service, brand, or company. Public opinion polls are conducted in a similar manner. Telemarketing techniques are also applied to other forms of electronic marketing using e-mail or fax messages, in which case they are frequently considered spam by receivers.

16.3.5: Vending Machines

A vending machine can dispense a wide variety of merchandise when the consumer inserts money into it.

Learning Objective

Explain the vending machine process

Key Points

- Vending machines have a huge variety of goods that they may dispense: snacks, beverages, alcohol, cigarettes, lottery tickets, consumer products, electronics, full meals, and even jewellery.

- The main example of a vending machine giving access to all merchandise after paying for one item is a newspaper vending machine (also called vending box) found mainly in the U.S. and Canada.

- Some products need to be prepared to become available. For example, tickets are printed or magnetized on the spot, and coffee is freshly concocted. Others, such as newspapers, are already ready for use.

Key Term

- vending machine

-

A automatic machine that accepts money and dispenses merchandise.

A vending machine is a machine which dispenses items such as snacks, beverages, alcohol, cigarettes, lottery tickets, consumer products and even gold and gems to customers automatically, after the customer inserts currency or credit into the machine . After paying, a product may become available by: the machine releasing it, so that it falls in an open compartment at the bottom, or into a cup, either released first, or put in by the customer; the unlocking of a door or drawer; or the turning of a knob. Some products need to be prepared to become available. For example, tickets are printed or magnetized on the spot, and coffee is freshly concocted. The most common form of vending machine, the snack machine, often uses a metal coil which rotates to release an ordered product.

Best Buy Vending Machine

This is a Best Buy Express vending machine at an airport terminal, stocked with electronics. These are referred to as automated retail kiosks.

The main example of a vending machine giving access to all merchandise after paying for one item is a newspaper vending machine (also called vending box) found mainly in the U.S. and Canada. It contains a pile of identical newspapers. After a sale, the door automatically returns to a locked position. A customer could open the box and take all of the newspapers or, for the benefit of other customers, leave all of the newspapers outside of the box, slowly return the door to an unlatched position, or block the door from fully closing. All of these possibilities are frequently discouraged, sometimes by a security clamp. The success of such machines is predicated on the assumption that the customer will be honest (hence the nickname “honor box”), and need only one copy.

A wide variety of goods can be dispensed by vending machines, and in some places, even burgers and steaks!

16.3.6: Mall Kiosks

A retail kiosk (or mall kiosk) is a store operated out of a merchant supplied kiosk.

Learning Objective

Explain the benefits and drawbacks of employing a retail kiosk (RMU)

Key Points

- Kiosks are located in shopping malls, airports, stadiums, or larger stores. Their placement guarantees high foot traffic from shoppers and offers opportunities for impulse sales.

- Holiday rents are generally term rents that encompass both November and December. These holiday rents are often three to four times the non-holiday rents for each of these two months.

- Benefits of kiosks include high visibility, low overhead, small inventories, and low or non-existent CAM, tax, utility, and marketing fees, as compared to their in-line storefront counterparts.

Key Term

- kiosk

-

A small enclosed structure, often freestanding, open on one side or with a window, used as a booth to sell newspapers, cigarettes, etc.

A retail kiosk (or mall kiosk) is a store operated out of a merchant supplied kiosk. It is typically enclosed with the operator located in the center and the customer approaching the vendor from across a counter. These units are located in shopping malls, airports, stadiums, or larger stores. The industry term for smaller units is retail merchandising unit (RMU) cart or mall cart. These smaller desk size units were created to avoid lease conflicts with existing stores with “kiosk” language exclusions and local fire codes requiring greater distance between units by placing them on wheels. RMUs function with the operator approaching the customer from the area surrounding the unit and showing or even demonstrating the product firsthand. Their placement guarantees high foot traffic from shoppers and offers opportunities for impulse sales .

Mall Kiosk

These are mall kiosks in Haifa Mall, Haifa, Israel.

RMUs are usually supplied by the property owner and licensed rather than leased. Kiosks are also available under the same conditions and may even be supplied by the property owner when they have been abandoned by former tenants. Rents vary by market conditions and mall traffic. Holiday rents are generally term rents that encompass both November and December with a combined sales breakpoint for the holiday term on short-term agreements or annual sales breakpoints on permanent agreements. These holiday rents are often three to four times the non-holiday rents for each of these two months.

Due to the high visibility of these units, which are most often located in the common areas of malls, these businesses can often gain a relatively trackable monthly sales figure after a three or four month trial. Many other benefits exist, such as low overhead, small inventories, and low or non-existent CAM, tax, utility, and marketing fees, as compared to their in-line storefront counterparts, which can often have fees equal to or in excess of the rents themselves.

16.3.7: Direct Selling

Direct selling is the marketing and selling of products directly to consumers, away from a fixed retail location.

Learning Objective

Explain the role of direct selling in retail

Key Points

- In contrast to franchising, the cost for an individual to start an independent direct selling business is typically very low with little or no required inventory or other cash commitments in the beginning.

- The World Federation of Direct Selling Associations (WFDSA) reports that its 59 regional member associations accounted for more than U.S. $114 billion in retail sales in 2007 through the activities of more than 62 million independent sales representatives.

- Direct selling is distinct from direct marketing because it is about individual sales agents reaching and dealing directly with clients, while direct marketing is about business organizations seeking a relationship with their customers without going through an agent/consultant or retail outlet.

Key Term

- Direct Marketing

-

is a channel-agnostic form of advertising that allows businesses and nonprofits organizations to communicate straight to the customer

Direct Selling in Retail

Direct selling is the marketing and selling of products directly to consumers, away from a fixed retail location. Peddling is the oldest form of direct selling. Modern direct selling is done through personal presentation and includes sales made through the party plan, one-on-one demonstrations, and other personal contact arrangements as well as internet sales.

The World Federation of Direct Selling Associations (WFDSA) reports that its 59 regional member associations accounted for more than U.S. $114 billion in retail sales in 2007 through the activities of more than 62 million independent sales representatives. The United States Direct Selling Association (DSA) reported that in 2000, 55 percent of adult Americans had at some point purchased goods or services from a direct selling representative, and 20 percent reported that they were currently (6 percent) direct selling representatives or had been in the past (14 percent).

According to the WFDSA, consumers benefit from direct selling because of the convenience and service it provides, including personal demonstrations and explanations of products, home delivery, and generous satisfaction guarantees. In contrast to franchising, the cost for an individual to start an independent direct selling business is typically very low with little or no required inventory or other cash commitments in the beginning.

Most direct selling associations, including the Bundesverband Direktvertrieb Deutschland (the direct selling association of Germany), the WFDSA, and the DSA, require their members to abide by a code of conduct ensuring a fair partnership both with customers and salesmen. Most national direct selling associations are represented in the World Federation of Direct Selling Associations (WFDSA).

Direct selling is distinct from direct marketing because it is about individual sales agents reaching and dealing directly with clients. Direct marketing is about business organizations seeking a relationship with their customers without going through an agent, consultant, or retail outlet. Direct selling frequently uses multi-level marketing rather than single-level marketing. In multi-level marketing, the salesperson is paid both for selling and for the sales made by the people he or she recruits or sponsors. In single-level marketing, the salesperson is paid only for the sales he or she makes individually.

Largest Direct Selling Companies

According to Direct Selling News, the largest direct selling companies by ‘revenue in 2011’ were:

- Avon Products, founded 1886, U.S. $ 11.3 billion

- Amway, founded 1959, U.S. $ 10.9 billion

- Herbalife, founded 1980, U.S. $ 3.5 billion

- Natura, founded 1969, U.S. $ 3.01 billion

- Vorwerk, founded 1883, U.S. $ 3.0 billion

- Mary Kay, founded 1963, U.S. $ 2.9 billion

- Tupperware, founded 1946, U.S. $ 2.6 billion

- Oriflame, founded 1967, U.S. $ 2.1 billion

- Nu Skin Enterprises, founded 1984, U.S. $ 1.7 billion

- Belcorp, founded 1967, U.S. $ 1.6 billion

Direct Selling

A peddler in Vietnam

16.4: Logistics

16.4.1: Distribution Modes

Cargo (or freight) is goods or produce transported, generally for commercial gain, by ship, aircraft, intermodal train, van, or truck.

Learning Objective

Compare aircraft cargo, train cargo and road cargo

Key Points

- Air cargo, commonly known as air freight, is collected by firms from shippers and delivered to customers. Aircraft were first used for carrying mail as cargo in 1911.

- Trains are capable of transporting large numbers of containers that come from shipping ports. Trains also are used for the transportation of steel, wood, and coal.

- Feight transport by rail is more economical and energy efficient than by road, especially when carried in bulk or over long distances. The main disadvantage of rail freight is its lack of flexibility. For this reason, rail has lost much of the freight business to road transport.

Key Term

- Cargo

-

(or freight) is goods or produce transported, generally for commercial gain, by ship, aircraft, intermodal train, van, or truck. In modern times, containers are used in most intermodal freight transport.

Cargo (or freight) is goods or produce transported, generally for commercial gain, by ship, aircraft, intermodal train, van, or truck. In modern times, containers are used in most intermodal freight transport.

Air cargo, commonly known as air freight, is collected by firms from shippers and delivered to customers. Aircraft were first used for carrying mail as cargo in 1911. Eventually, manufacturers started designing aircraft for other types of freight as well. There are many commercial aircraft suitable for carrying cargo such as the Boeing 747 and the bigger An-124, which was purposely built for easy conversion into a cargo aircraft. Such large aircraft employ quick-loading containers known as “unit load devices (ULDs)”, much like containerized cargo ships. The ULDs are located in front section of the aircraft. Most nations own and utilize large numbers of cargo aircraft, such as the C-17 Globemaster III, for their logistical needs.

Trains are capable of transporting large numbers of containers that come from shipping ports. Trains are also used for the transportation of steel, wood, and coal. They are used because they can carry a large amount and, generally, have a direct route to the destination. Under the right circumstances, freight transport by rail is more economical and energy efficient than by road, especially when carried in bulk or over long distances. The main disadvantage of rail freight is its lack of flexibility. For this reason, rail has lost much of the freight business to road transport. Rail freight is often subject to trans-shipment costs, since it must be transferred from one mode of transportation to another. Practices, such as containerization, aim at minimizing these costs. Many governments are currently trying to encourage shippers to use trains more often because of the environmental benefits. Many firms, such as Parcelforce, FedEx, R+L Carriers, and U-Haul, transport all types of cargo by road. Delivering everything from letters to houses to cargo containers, these firms offer fast, sometimes same-day, delivery. A good example of road cargo is food, as supermarkets require deliveries every day to keep their shelves stocked with goods. Retailers of all kinds rely upon delivery trucks, be they full-size, semi trucks or smaller delivery vans.

Cargo

Cargo net being used to unload sacks from a ship at Haikou New Port, Haikou City, Hainan, China.

16.4.2: Inventory Management

Inventory represents finished and unfinished goods that have not yet been sold by a company.

Learning Objective

Explain why and how companies keep inventory

Key Points

- Inventories are maintained because time lags in moving goods to customers could otherwise put sales at risk.

- Inventories are maintained as buffers to meet uncertainties in demand, supply and movements of goods.

- There are four stages of inventory: raw material, work in progress, finished goods, and goods for resale.

Key Terms

- raw materials

-

Materials and components scheduled for use in making a product.

- Finished goods

-

Goods ready for sale to customers.

- Work in process

-

Materials and components that have began their transformation to finished goods.

Example

- A canned food manufacturer’s materials inventory includes the ingredients to form the foods to be canned, empty cans and their lids (or coils of steel or aluminum for constructing those components), labels, and anything else (solder, glue, etc.) that will form part of a finished can. The firm’s work in process includes those materials from the time of release to the work floor until they become complete and ready for sale to wholesale or retail customers. This may be vats of prepared food, filled cans not yet labeled or sub-assemblies of food components. It may also include finished cans that are not yet packaged into cartons or pallets. Its finished good inventory consists of all the filled and labeled cans of food in its warehouse that it has manufactured and wishes to sell to food distributors (wholesalers), to grocery stores (retailers), and even perhaps to consumers through arrangements like factory stores and outlet centers.

Reasons for Keeping Inventory

In many cases (such as retail), a business must have its product on hand in order to complete a sale. For these companies, the reason for keeping one of each item on hand (in inventory) is that it enables them to make sales and capture revenue. However, many businesses keep more than one of every item on hand and also keep raw materials and unfinished goods on stock in factories. Why do they do this?

There are three basic reasons for keeping an inventory:

- Time: The time lags present in the supply chain, from supplier to user at every stage, requires that you maintain certain amounts of inventory to use in this lead time. However, in practice, inventory is to be maintained for consumption during variations in lead time. Lead time itself can be addressed by ordering that many days in advance.

- Uncertainty: Inventories are maintained as buffers to meet uncertainties in demand, supply and movements of goods.

- Economies of scale: Ideal condition of “one unit at a time, at a place where a user needs it, when he needs it” principle tends to incur lots of costs in terms of logistics. So bulk buying, movement and storing brings in economies of scale, thus inventory. All these stock reasons can apply to any owner or product.

Managing Inventory

Inventory management is primarily about specifying the location and amount of stocked goods. Optimizing inventory management requires balancing many factors, including:

- Replenishment lead time

- Carrying costs of inventory

- Asset management

- Inventory forecasting

- Inventory valuation

- Inventory visibility

- Future inventory price forecasting

- Physical inventory

- Available physical space for inventory

- Quality management

- Replenishment

- Returns and defective goods

- Demand forecasting

Balancing these competing requirements leads to optimal inventory levels, which is an on-going process as the business needs to react to the wider environment. Optimal inventory levels are those that maximize profit from sales, while minimizing cost from storage, shipping, and working capital deployment.

While accountants often discuss inventory in terms of goods for sale, other organizations (such as manufacturers, service-providers and not-for-profits) also have inventories (fixtures, furniture, supplies, etc.) that they do not intend to sell. Manufacturers’, distributors’, and wholesalers’ inventory tends to cluster in warehouses. Retailers’ inventory may exist in a warehouse or in a shop or store accessible to customers. Inventories not intended for sale to customers or to clients may be held in any premises an organization uses. Stock ties up cash and, if uncontrolled, it will be impossible to know the actual level of stocks, and therefore impossible to control them.

Stages of Inventory

While the reasons for holding stock were covered earlier, most manufacturing organizations usually divide their “goods for sale” inventory into:

- Raw materials: materials and components scheduled for use in making a product

- Work in process (WIP): materials and components that have began their transformation to finished goods

- Finished goods: goods ready for sale to customers

- Goods for resale: returned goods that are salable

Inventory

Inventory in a warehouse

16.4.3: Warehousing

A warehouse is a commercial building for storage of goods.

Learning Objective

Explain the logistics of warehousing

Key Points

- Warehouses are used by manufacturers, importers, exporters, wholesalers, transport businesses, customs, etc.

- Some warehouses are completely automated, and require only operators to work and handle all the task.

- Warehouse management monitors the progress of products through the warehouse. It involves the physical warehouse infrastructure, tracking systems, and communication between product stations.

Key Terms

- Auto ID Data Capture (AIDC)

-

Warehouse management systems often utilize AIDC technology, such as barcode scanners, mobile computers, wireless LANs and potentially radio-frequency identification (RFID) to efficiently monitor the flow of products.

- Warehouse management

-

The progress of products through the warehouse. It involves the physical warehouse infrastructure, tracking systems, and communication between product stations.

A warehouse is a commercial building for storage of goods. Warehouses are used by manufacturers, importers, exporters, wholesalers, transport businesses, customs, etc. They are usually large plain buildings in industrial areas of cities and towns and villages. They usually have loading docks to load and unload goods from trucks. Sometimes warehouses are designed for the loading and unloading of goods directly from railways, airports, or seaports. They often have cranes and forklifts for moving goods, which are usually placed on ISO standard pallets and loaded into pallet racks. Stored goods can include any raw materials, packing materials, spare parts, components, or finished goods associated with agriculture, manufacturing, or commerce.

Some warehouses are completely automated, and require only operators to work and handle all the tasks. Pallets and products move on a system of automated conveyors, cranes, and automated storage and retrieval systems coordinated by programmable logic controllers and computers running logistics automation software. These systems are often installed in refrigerated warehouses where temperatures are kept very cold to keep product from spoiling, especially in electronics warehouses where they require specific temperatures to avoid damaging the parts, and also where land is expensive, as automated storage systems can use vertical space efficiently. These high-bay storage areas are often more than ten meters (33 feet) high, with some over 20 meters (65 feet) high. Automated storage systems can be built up to 40m high.

Warehouse management monitors the progress of products through the warehouse. It involves the physical warehouse infrastructure, tracking systems, and communication between product stations. Warehousing is critical in saving costs and timely order fulfillment, and today it is a vital part of supply chain management demand management. Even production management is to a great extent dependent on warehouse management. Efficient warehouse management gives a cutting edge to a retail chain distribution company. It should start at the container design stage of a product and not at the delivery of material in the warehouse.

Warehouse management systems often utilize Auto ID Data Capture (AIDC) technology, such as barcode scanners, mobile computers, wireless LANs and potentially radio-frequency identification (RFID) to efficiently monitor the flow of products. Once data has been collected, there is either a batch synchronization with, or a real-time wireless transmission to a central database. The database can then provide useful reports about the status of goods in the warehouse. A set of computerized procedures handle the receipt of stock and returns into a warehouse facility, model and manage the logical representation of the physical storage facilities (e.g., racking), manage the stock within the facility, and enable a seamless link to order processing and logistics management in order to pick, pack and ship product out of the facility.

A Warehouse

Inside Green Logistics Co., Kotka, Finland. The image shows goods loaded on pallets to the left of the aisle, and stacked pallets with no loads to the right of the aisle.

16.4.4: Materials Handling

Materials handling is the movement, storage, control, and protection of materials during their manufacturing, distribution, consumption, and disposal.

Learning Objective

Explain the importance of efficient material handling

Key Points

- Material handling systems range from simple pallet rack and shelving projects to complex overhead conveyor systems and automated storage and retrieval systems (AS/RS). Material handling can also consist of sorting and picking, as well as automatic guided vehicles.

- The Material Handling System (MHS) is a fundamental part of a flexible manufacturing system, since it interconnects the different processes supplying and taking out raw material, workpieces, subproducts, parts, and final products.

- There are several ways to determine if the material handling equipment is achieving peak efficiency. These include capturing all relevant data related to the warehouse’s operations, such as the Stock Keeping Unit (SKU).

Key Terms

- Material Handling System (MHS)

-

A fundamental part of a flexible manufacturing system, since it interconnects the different processes supplying and taking out raw material, workpieces, subproducts, parts, and final products.

- Stock Keeping Unit (SKU)

-

A unique identifier for each distinct product and service that can be purchased in business.

Material Handling is the movement, storage, control and protection of materials, goods, and products throughout the process of manufacturing, distribution, consumption, and disposal. This trade channel is necessary when agents cannot directly sell to industrial users. The focus is on the methods, mechanical equipment, systems, and related controls used to achieve these functions.

The material handling industry manufactures and distributes the equipment and services required to implement material handling systems. Material handling systems range from simple pallet rack and shelving projects, to complex overhead conveyor systems and automated storage and retrieval systems (AS/RS). Material handling also can consist of sorting and picking, as well as automatic guided vehicles. The material handling system (MHS) is a fundamental part of a flexible manufacturing system, since it interconnects the different processes supplying and taking out raw material, workpieces, sub-products, parts, and final products. Due to the automated nature of the whole production process, the MHS must respond in concert with timeliness for all requirements of the processes and systems. The MHS is composed of warehouses, buffers, conveyors, transportation vehicles or systems, part sorters, feeders, and manipulators. Specialized material handling equipment is used to increase output, control costs, and maximize productivity.

There are several ways to determine if the material handling equipment is achieving peak efficiency. These include capturing all relevant data related to the warehouse’s operation (such as the stock keeping unit (SKU)), measuring how many times an item is “touched” from the time it is ordered until it leaves the building, making sure you are using the proper picking technology, and keeping system downtime to a minimum.

A Forklift

Forklift trucks are common in material handling.

16.4.5: Shipping and Transportation

Shipping is a physical process of transporting commodities and merchandise goods and cargo, by land, air, and sea.

Learning Objective

Compare land, air, and sea methods of shipment

Key Points

- Cost, insurance, and freight (CIF): Insurance and freight are paid by the exporter to the specified location. For example, at CIF Los Angeles, the exporter pays the ocean shipping/air freight costs to Los Angeles including the insurance of cargo.

- Shipment of cargo by trucks, directly from the shipper’s place to the destination, is known as a door to door shipment, and more commonly called multimodal transport system. Trucks and trains make deliveries to sea ports and air ports where cargo is moved in bulk.

- Freight on board, or free on board (FOB): the exporter delivers the goods at the specified location (and on board the vessel). Costs paid by the exporter include loading, securing, etc.

Key Term

- insurance

-

A means of indemnity against a future occurrence of an uncertain event.

Shipping is a physical process of transporting commodities, merchandise goods, and cargo, by land, air, and sea.

Land or “ground” shipping can be by train or by truck. In air and sea shipments, ground transportation is required to take the cargo from its place of origin to the airport or seaport, and then to its destination, since it is not always possible to establish a production facility near ports due to limited coastlines of countries. Ground transportation is typically more affordable than air shipments, but more expensive than shipping by sea, especially in developing countries, where inland infrastructure is not efficient.

Shipment of cargo by trucks, directly from the shipper’s place to the destination, is known as a door to door shipment, and more commonly called multimodal transport system. Trucks and trains make deliveries to sea ports and air ports where cargo is moved in bulk.

Much shipping is done aboard actual ships. An individual nation’s fleet, and the people that crew it, are referred to as its merchant navy or merchant marine. Merchant shipping is lifeblood to the world economy, carrying 90% of international trade with 102,194 commercial ships worldwide. The term “shipping” in this context originated from the shipping trade of wind power ships, and has come to refer to the delivery of cargo and parcels of any size above the common mail of letters and postcards.

Common trading terms used in shipping goods internationally include:

- Freight on board, or free on board (FOB): the exporter delivers the goods at the specified location (and on board the vessel). Costs paid by the exporter include loading, securing, etc. For example, “FOB JNPT” means that the exporter delivers the goods to the Jawahar lal Nehru Port, India, and pays for the cargo to be loaded and secured on the ship.

- Cost and freight (C&F, CFR, CNF): Insurance is payable by the importer, and the exporter pays all expenses incurred in transporting the cargo from its place of origin to the port/airport and ocean freight/air freight to the port/airport of destination. For example, C&F Los Angeles (the exporter pays the ocean shipping/air freight costs to Los Angeles). Most governments ask their exporters to trade on these terms to promote their exports.

- Cost, insurance, and freight (CIF): Insurance and freight are paid by the exporter to the specified location. For example, at CIF Los Angeles, the exporter pays the ocean shipping/air freight costs to Los Angeles including the insurance of cargo. This also states that responsibility of the shipper ends at the Los Angeles port.

Shipping

Harbour cranes unloading cargo from a container ship at the Jawaharlal Nehru Port, Navi Mumbai, India

16.4.6: Supply Chain Management

Supply chain management is the management of the network of interconnected steps involved in the provision of product and service packages.

Learning Objective

Explain the problems that are solved by supply chain management

Key Points

- Supply chain management spans all movement and storage of raw materials, work-in-process inventory, and finished goods from point of origin to point of consumption.

- Distribution Network Configuration: number, location, and network missions of suppliers; production facilities; distribution centers; warehouses; cross-docks; and customers.

- Supply chain management addresses the following issues: distribution network configuration, distribution strategy, logistical activities, information, and cash flow.

Key Terms

- Work in process

-

Work in process (acronym: WIP) or in-process inventory includes the set at large of unfinished items for products in a production process.

- raw materials

-

A raw material is the basic material from which a good product is manufactured or made, frequently used with an extended meaning.

- Finished goods

-

goods that are completed as to manufacturing but not yet sold or distributed to the end-user.

Supply chain management (SCM) is the management of a network of interconnected businesses involved in the provision of product and service packages required by the end customers in a supply chain. Supply chain management spans all movement and storage of raw materials, work-in-process inventory, and finished goods from point of origin to point of consumption.

Another definition is provided by the APICS Dictionary, when it defines SCM as the “design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronizing supply with demand and measuring performance globally. “

Supply chain management must address the following problems:

Distribution network configuration: number, location and network missions of suppliers, production facilities, distribution centers, warehouses, cross-docks and customers.

Distribution strategy: questions of operating control (centralized, decentralized or shared); delivery scheme (e.g., direct shipment, pool point shipping, or cross docking), DSD (direct store delivery), closed loop shipping; mode of transportation (e.g., motor carrier, including truckload, LTL, or parcel); railroad; intermodal transport, including TOFC (trailer on flatcar), and COFC (container on flatcar); ocean freight; airfreight; replenishment strategy (e.g., pull, push or hybrid); and transportation control (e.g., owner-operated, private carrier, common carrier, contract carrier, or 3PL).

Trade-offs in logistical activities: The above activities must be well coordinated in order to achieve the lowest total logistics cost. Trade-offs may increase the total cost if only one of the activities is optimized. For example, full truckload (FTL) rates are more economical on a cost per pallet basis than less than truckload (LTL) shipments. If, however, a full truckload of a product is ordered to reduce transportation costs, there will be an increase in inventory holding costs, which may increase total logistics costs. It is, therefore, imperative to take a systems approach when planning logistical activities. These trade offs are key to developing the most efficient and effective Logistics and SCM strategy.

Information: Integration of processes through the supply chain to share valuable information, including demand signals, forecasts, inventory, transportation, potential collaboration, etc.

Inventory management: Quantity and location of inventory, including raw materials, work-in-process (WIP), and finished goods.